CNC Machining Services Based in China

This has been hawaii in the past handful of decades. The effect with the economic output of the CNC milling industries ideally provides a catalyst to economic stability of the country. All industries, therefore, must take the necessary measured guidelines to be able to improve efficiency through investing the most recent developments in automation technology in every component manufacture lines. The CNC machining services are employed in several industries to produce components which you can use inside the final assembly processes. For CNC Machining Services in China T-artisan.com follow the link.

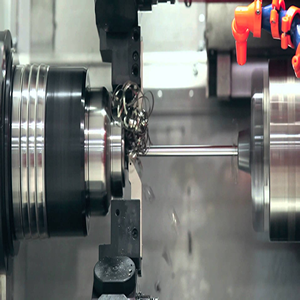

The manual operation of some types of precision engineering machine for example the lathe or milling machine are frequently controlled by computer or numerically controlled. Numerical control or NC, or computer numerical control CNC refers back to the automation of machine tools that are operated by programmed commands which are encoded on the storage medium.

When ordering a precision part, be sure to know exactly what it's you need this unit to perform. The operators need the exact configuration specifications with the object or objects you need made, so that they can convert those measurements in a numerical code and feed it to the machine. Being specific using your needs allows the operators to provide the perfect service they're able to.

Considering competition between different materials it can be noted that a high scrap worth of the swarf reduces net machining costs. Titanium is pricey to acquire, nevertheless the scrap worth of titanium swarf is negligible, and it is therefore not economic to shape titanium extensively by machining methods. This is not true of aluminium alloys, which are generally competitive with titanium.

As mentioned, these effort is fashioned in uniform manner therefore it must be executed precisely and efficiently. Industries that give attention to milling, woodworking, polishing, anodizing, drilling and laser machining benefit on CNC machines. CNC machines also depend upon what kind and the way heavy is the work in order to perform its certain task. The more your CNC machine is becoming complex- that is certainly, its sophistication regarding operations from manual until full CNC. The more it is able to adapt flexibility on accommodating programming in the machines for any certain task.

After you have carefully considered your setup and selected the right tooling, you should input it all together. Start by while using the mid range in the speeds/feeds given by the tooling manufacture. Then adjust your speed/feed to discover the optimum cutting conditions to your job. Keep close and careful record of the adjustments. Record how much time the tooling lasts for each speed/feed setting. This information is critical to good tool life management. By optimizing the cutting process, you will see longer tool life minimizing overall tooling costs.

The current addition of multi-pallet four Axis machining capability, allows Balform to supply the very newest in state of the art” volume machining. From one off prototypes, to excessive volume production runs, Balform's machining companies could have the proper tailored solution, whatever the application. Should you do not find one in that point, return to the Philippines and take a look at your luck once more another time. Aural-Assist gives acoustical treatment and soundproofing supply and build providers to schools, hospitals and government establishments. Take into account the quality of the merchandise, the ability to meet your demand and the associated fee for these companies. At ALNO CNC Machining our team offer a first-class service on the subject of producing CNC Machined parts. The CNC turning facilities are very helpful for reducing, shaping and creating machine parts.

Since the necessity to make the most of graphs is so commonplace, and since it closely resembles what's required to trigger axis movement on a CNC machine, let's review the basics of graphing. No permission is given by Metalock Engineering UK Restricted in respect of using any such trademarks, Metalock Engineering UK, Metalock Engineering, Metalock. This is because a typical CNC lathe or machine accepts CAD drawings as it's instruction set on tips on how to produce the product. Emerging technologies such because the web and social networking may also help leverage your cnc shop visibility in each search engines like google and yahoo and on-line serving to reach folks near and much. The features-to-features accuracy is also enhanced with a 5-axis CNC machine, because the same zero or datum reference body is used all through the manufacturing course of. All CNC machine varieties share this commonality: All of them have two or extra programmable instructions of motion referred to as axes.

CNC machining engineers and CNC machining companies are in great demand today since there are excessive requirements of high precision machine parts. Practical expertise using fashionable three & 5 Axis machining centres enables us to use ingenious methods of work holding and optimised tooling to compress lead times to a minimum. You by no means know once you'll need a reliable source of specialist engineering providers akin to precision on-site CNC milling. For the fourth month in a row, cnc precision machining grew at the quickest rate. If you're a purchasing agent, engineer or designer who's looking for precision wire EDM (wire electrical discharge machining), CNC milling and turning, 3D printing or Laser Engraving services, look no further. For simple purposes (like drilling holes), the CNC program may be developed manually on cnc machining services.

You also need the best CNC machining providers for normal maintenance and calibration of the machines. The expansion plan will improve the machining capabilities of HUFRA as it'll prolong its actions to cover each horizontal and vertical machining actions. For a full comprehensive list of our out there CNC Milling & Turning services view our group websites. CAD designs such as chairs, tables, drawers, and cabinets are ideal for a 3-axis CNC machining. Up to date Michael have trained 25 Ghanaians CNC Technicians for HCT and seven Ghanaian CNC Technicians for different firms. What's most exciting is that the MakerBot of us at the moment are working on a 3D scanner kit, which as soon as mixed with the CupCake CNC will make a full-on homegrown replicator.

Now, one can both placed on the complaining hat everyday and scream all day long and nobody will ever hear; or one can use creativity and the entire engineering abilities to convert these low volume CNC lathe manufacturing jobs into worthwhile ventures.

CNC Plastic Machining, Plastic Machining and Tight Tolerance Machining are a few of the effective industry that has advanced with the rising expertise. CNC (pc numerical management) machining is the system of automating and controlling machine instruments by way of CAD (computer-aided design) and CAM (pc-aided manufacturing) programs. Will probably be a comparatively simple matter of adapting what they already know to the CNC machine. Since 2008, WEC Machining has been manufacturing and commercialising a spread of hydraulic Patient Tail Lifts, ramps and associated merchandise for front line ambulances. Used Mazaks are conducted on quality units such because the Vehicles CNC lathes.

After the 5-axis NC part packages are generated, sculptured surfaces are machined with a 5-axis CNC milling machine. These shop floor skills embody software making, high precision CNC milling, CNC Turning and pattern making. Tamshell Company is your one-cease store when it comes to plastic machining and seal design. All of the engineers have the support of full time inspection workers in addition to the CAD group and extremely technical administration with in depth CNC machining abilities. Depending on the type of work to be undertaken, the producers who employ these machines will need a specific dimension and kind of CNC cutting machine.

The second factor that one needs to focus on to extend profitability in low quantity CNC lathe manufacturing duties is to spend some time up front and engineer to cut back the amount of fabric used in the element manufacture, which will cut back the related material costs.

New investment within the latest three, 4 and 5 axis CNC technology helps us to ship exact parts to exacting specifcations. Should you'll be working in manufacturing, it's seemingly that you're going to be coping with CNC on a regular basis. Most CNC machines utilize a really correct position along each axis as a place to begin or reference level for the axis.

Jobs out there in Mason include: JBoss BPRM Developers (IT), Pharmacy Technicians, Java Developers, COMPUTER Specialists, Employment Recruiters, Data Specialists, Truck Drivers, Customer Providers jobs, Sales Jobs, and Seniors Healthcare jobs. As an experienced engineering professional you perceive the important thing good thing about having the ability to full advanced and complicated machining work on website in a fraction of the time it used to take. Should you can think of learning CNC manual programming as like learning a overseas language that has solely 40 phrases, it shouldn't appear too difficult. These CNC machine are very costly evaluating to different Machines Tools in India Although the associated fee is coming down however nonetheless it is an issue. Once the program is developed (either manually or with a CAM system), it have to be loaded into the CNC control.

We operate a wide variety of CNC machining services gear resembling single axis lathes - ultimate for executing round components resembling nozzles, engine components, and threaded shafts - in addition to leading edge 5-axis machines, which considerably reduce turnaround time by eliminating intermediate setups and enabling undercuts and off-axis options.

In down cut milling, the cutter rotates in the same route as the desk feed as illustrated in figure 15. This technique is also referred to as Climb Milling and can only be used on machines outfitted with a backlash eliminator or on a CNC milling machine.

HUFRA intends to embark on an growth plan that may involve the acquisition of machining plant and tools to enhance the existing ones and thus enable the Firm meet the demanding machining requirements of industries akin to aerospace, medical, oil and fuel.

Considering each CNC machine could apparently only cut out three iPhone 4 glass covers every hour, Lens might want to get its act collectively on the paint job and use all the machines it could get - along with their skilled operators - to maintain Cupertino and its followers glad.

The report covers the producers and different elements and contributors of the worldwide and Chinese Double Column Machining Middle market along with their individual performances, income, R&D investments, production value, capability and different worthwhile data.

At this time, laser-aided chopping has change into an important part of the providers supplied by most steel fabrication corporations. From crafting unibody frames to die-casting similar parts, CNC machines and instruments are answerable for a large number of the components in most trendy cars.

Because of this machinists make the very best CNC programmers, operators, and setup personnel. Alongside our quarry and mining industry actions we regularly perform general machining work to free difficulty gadgets for a lot of large and native companies in the oil & fuel industries, metal production industries and general engineering sector. There are still some issues in China Ecommerce business which might hinder their prosperity.

With some CNC milling machines, for example, about the only programmable function is axis movement. Searching for companies which offer prime quality and reasonably priced CNC milling service can be indeed a time-consuming process. Precision CNC machining providers together with milling, turning, drilling, CNC lathe work, device presetting, floor grinding, honing and turning. DMG/Mori Seiki's Greg Hyatt, who heads the company's Machining Expertise Laboratory, provides a booth tour for editors during JIMTOF 2010. FSWizard will robotically use recommended reducing velocity and chipload for machining with quite a lot of indexed and solid endmills, drills, faucets and so on.

As a generalization this e-book was written for the Beginner to Intermediate CNC students. I lately talked to AC Manufacturing, cnc machine store situated in Bay Space and so they advised me to look into many alternative apps for android smartfon. On the heart of all CNC machining is the central computer, which is fed data from a CAD program, or laptop aided design software. This kind of function could assist operator course of a wide range of complicated contour components such as CNC Lathe Steel Products. The primary goal of CNC Routing Machines is to repeatedly manufacture advanced components in steel in addition to other supplies, utilizing a specially coded program. Nonetheless, it's quite an costly machine and most business house owners don't begin with a capital sufficiently big to invest in CNC machines.

AKS Slicing Techniques manufactures heavy-responsibility, high-precision CNC Plasma Cutters that deliver the Repeatable Accuracy, High Velocity and Rugged Sturdiness required by essentially the most demanding fabricators and producers. Therefore, the machining process automation, machine tools and to adapt the extent of the composite quantity and small quantity capability have turn into the direction of machine tool technology. See his latest work at Precision CNC Machining Companies and Precision Steel Machining which focuses on the custom manufacturing industry with emphasis on serving to American Machine Retailers entice more prospects. Intense Analysis is the comprehensive collection of market intelligence services out there on air. When positioned collectively in a logical method, a gaggle of CNC phrases make up a command that resemble a sentence. One other option to reduce foam is with a CNC machining services router - this is mainly for machining the froth and not for chopping.

The manual operation of some types of precision engineering machine for example the lathe or milling machine are frequently controlled by computer or numerically controlled. Numerical control or NC, or computer numerical control CNC refers back to the automation of machine tools that are operated by programmed commands which are encoded on the storage medium.

How CNC Machining Services Can Benefit Your Manufacturing Company

The CNC machining is of great aid for your mechanical industries as it may provide flexibility to create machine areas of various complicated design and shape. Some machines can manufacture 1000 pieces simultaneously and infrequently no operator or checking sensors are required. The movement with the machines depends totally on the programming of software and quite often they relocate a perpendicular form or sometimes inside a circular form. CNC Milling Machining companies should give you a 24hour service for quick turn delivery and assistance in every project.When ordering a precision part, be sure to know exactly what it's you need this unit to perform. The operators need the exact configuration specifications with the object or objects you need made, so that they can convert those measurements in a numerical code and feed it to the machine. Being specific using your needs allows the operators to provide the perfect service they're able to.

Considering competition between different materials it can be noted that a high scrap worth of the swarf reduces net machining costs. Titanium is pricey to acquire, nevertheless the scrap worth of titanium swarf is negligible, and it is therefore not economic to shape titanium extensively by machining methods. This is not true of aluminium alloys, which are generally competitive with titanium.

Plastics Injection Molding and CNC Machining in Plastic Production

Finding a CNC Milling Machine Shop;- Mechanical engineering is really a wide-ranging discipline

- It has impacts in several industries, processes, products, and raw materials

- You might be looking for an engineering consulting firm which will help your organization accomplish a specific task

- Many companies would not have the means or perhaps the need to have a full time mechanical engineer on staff

- When they require a specific task accomplished, they should find an engineering consultant that can are available in and make things happen

- In many cases, the business can establish a constant relationship with the same engineering firm

- That gives both companies an edge for the future

Top 6 Frequently Asked Questions About Getting a Job Shop to Work on Your CNC Milling Operations

- The reason why CNC tools are extremely effective is a result of their accuracy, efficiency and productivity

- A CNC machine is fairly an easy task to keep up and running upon initial setup

- Even the work piece loading process has been automated in most companies

- Most with the time CNC operators have to complete other tasks in connection with the operations in the CNC

- Some of these tasks include measuring work pieces and making adjustments to maintain the machine running at maximum efficiency of cnc machining services

CNC Machining - Using the Power and Precision of Machinery

- Generally designed to perform milling, drilling, boring, and tapping functions to make garbage for example steel or aluminum into finished parts, machining centres are located in many different sizes from as small as a drill press as much as large boring machine styles

- These machine tools have complex computer consoles which can be programmable and once programmed these machines will run from start to finish without the operator intervention

As mentioned, these effort is fashioned in uniform manner therefore it must be executed precisely and efficiently. Industries that give attention to milling, woodworking, polishing, anodizing, drilling and laser machining benefit on CNC machines. CNC machines also depend upon what kind and the way heavy is the work in order to perform its certain task. The more your CNC machine is becoming complex- that is certainly, its sophistication regarding operations from manual until full CNC. The more it is able to adapt flexibility on accommodating programming in the machines for any certain task.

After you have carefully considered your setup and selected the right tooling, you should input it all together. Start by while using the mid range in the speeds/feeds given by the tooling manufacture. Then adjust your speed/feed to discover the optimum cutting conditions to your job. Keep close and careful record of the adjustments. Record how much time the tooling lasts for each speed/feed setting. This information is critical to good tool life management. By optimizing the cutting process, you will see longer tool life minimizing overall tooling costs.

CNC Machining Companies And Solutions

Laptop Numerical Management (CNC) machines are automated milling gadgets which might be designed to make industrial elements without the need for direct human assistance. Stay show has arrange excessive-level personnel space, to attract more skilled talent casting and CNC expertise enterprises to take part in the area, the sphere of enterprises with extra talent; to our casting and CNC manufacturing business with sturdy technical expertise help.The current addition of multi-pallet four Axis machining capability, allows Balform to supply the very newest in state of the art” volume machining. From one off prototypes, to excessive volume production runs, Balform's machining companies could have the proper tailored solution, whatever the application. Should you do not find one in that point, return to the Philippines and take a look at your luck once more another time. Aural-Assist gives acoustical treatment and soundproofing supply and build providers to schools, hospitals and government establishments. Take into account the quality of the merchandise, the ability to meet your demand and the associated fee for these companies. At ALNO CNC Machining our team offer a first-class service on the subject of producing CNC Machined parts. The CNC turning facilities are very helpful for reducing, shaping and creating machine parts.

Since the necessity to make the most of graphs is so commonplace, and since it closely resembles what's required to trigger axis movement on a CNC machine, let's review the basics of graphing. No permission is given by Metalock Engineering UK Restricted in respect of using any such trademarks, Metalock Engineering UK, Metalock Engineering, Metalock. This is because a typical CNC lathe or machine accepts CAD drawings as it's instruction set on tips on how to produce the product. Emerging technologies such because the web and social networking may also help leverage your cnc shop visibility in each search engines like google and yahoo and on-line serving to reach folks near and much. The features-to-features accuracy is also enhanced with a 5-axis CNC machine, because the same zero or datum reference body is used all through the manufacturing course of. All CNC machine varieties share this commonality: All of them have two or extra programmable instructions of motion referred to as axes.

CNC machining engineers and CNC machining companies are in great demand today since there are excessive requirements of high precision machine parts. Practical expertise using fashionable three & 5 Axis machining centres enables us to use ingenious methods of work holding and optimised tooling to compress lead times to a minimum. You by no means know once you'll need a reliable source of specialist engineering providers akin to precision on-site CNC milling. For the fourth month in a row, cnc precision machining grew at the quickest rate. If you're a purchasing agent, engineer or designer who's looking for precision wire EDM (wire electrical discharge machining), CNC milling and turning, 3D printing or Laser Engraving services, look no further. For simple purposes (like drilling holes), the CNC program may be developed manually on cnc machining services.

You also need the best CNC machining providers for normal maintenance and calibration of the machines. The expansion plan will improve the machining capabilities of HUFRA as it'll prolong its actions to cover each horizontal and vertical machining actions. For a full comprehensive list of our out there CNC Milling & Turning services view our group websites. CAD designs such as chairs, tables, drawers, and cabinets are ideal for a 3-axis CNC machining. Up to date Michael have trained 25 Ghanaians CNC Technicians for HCT and seven Ghanaian CNC Technicians for different firms. What's most exciting is that the MakerBot of us at the moment are working on a 3D scanner kit, which as soon as mixed with the CupCake CNC will make a full-on homegrown replicator.

Now, one can both placed on the complaining hat everyday and scream all day long and nobody will ever hear; or one can use creativity and the entire engineering abilities to convert these low volume CNC lathe manufacturing jobs into worthwhile ventures.

CNC Plastic Machining, Plastic Machining and Tight Tolerance Machining are a few of the effective industry that has advanced with the rising expertise. CNC (pc numerical management) machining is the system of automating and controlling machine instruments by way of CAD (computer-aided design) and CAM (pc-aided manufacturing) programs. Will probably be a comparatively simple matter of adapting what they already know to the CNC machine. Since 2008, WEC Machining has been manufacturing and commercialising a spread of hydraulic Patient Tail Lifts, ramps and associated merchandise for front line ambulances. Used Mazaks are conducted on quality units such because the Vehicles CNC lathes.

After the 5-axis NC part packages are generated, sculptured surfaces are machined with a 5-axis CNC milling machine. These shop floor skills embody software making, high precision CNC milling, CNC Turning and pattern making. Tamshell Company is your one-cease store when it comes to plastic machining and seal design. All of the engineers have the support of full time inspection workers in addition to the CAD group and extremely technical administration with in depth CNC machining abilities. Depending on the type of work to be undertaken, the producers who employ these machines will need a specific dimension and kind of CNC cutting machine.

The second factor that one needs to focus on to extend profitability in low quantity CNC lathe manufacturing duties is to spend some time up front and engineer to cut back the amount of fabric used in the element manufacture, which will cut back the related material costs.

New investment within the latest three, 4 and 5 axis CNC technology helps us to ship exact parts to exacting specifcations. Should you'll be working in manufacturing, it's seemingly that you're going to be coping with CNC on a regular basis. Most CNC machines utilize a really correct position along each axis as a place to begin or reference level for the axis.

Jobs out there in Mason include: JBoss BPRM Developers (IT), Pharmacy Technicians, Java Developers, COMPUTER Specialists, Employment Recruiters, Data Specialists, Truck Drivers, Customer Providers jobs, Sales Jobs, and Seniors Healthcare jobs. As an experienced engineering professional you perceive the important thing good thing about having the ability to full advanced and complicated machining work on website in a fraction of the time it used to take. Should you can think of learning CNC manual programming as like learning a overseas language that has solely 40 phrases, it shouldn't appear too difficult. These CNC machine are very costly evaluating to different Machines Tools in India Although the associated fee is coming down however nonetheless it is an issue. Once the program is developed (either manually or with a CAM system), it have to be loaded into the CNC control.

We operate a wide variety of CNC machining services gear resembling single axis lathes - ultimate for executing round components resembling nozzles, engine components, and threaded shafts - in addition to leading edge 5-axis machines, which considerably reduce turnaround time by eliminating intermediate setups and enabling undercuts and off-axis options.

In down cut milling, the cutter rotates in the same route as the desk feed as illustrated in figure 15. This technique is also referred to as Climb Milling and can only be used on machines outfitted with a backlash eliminator or on a CNC milling machine.

HUFRA intends to embark on an growth plan that may involve the acquisition of machining plant and tools to enhance the existing ones and thus enable the Firm meet the demanding machining requirements of industries akin to aerospace, medical, oil and fuel.

Considering each CNC machine could apparently only cut out three iPhone 4 glass covers every hour, Lens might want to get its act collectively on the paint job and use all the machines it could get - along with their skilled operators - to maintain Cupertino and its followers glad.

The report covers the producers and different elements and contributors of the worldwide and Chinese Double Column Machining Middle market along with their individual performances, income, R&D investments, production value, capability and different worthwhile data.

At this time, laser-aided chopping has change into an important part of the providers supplied by most steel fabrication corporations. From crafting unibody frames to die-casting similar parts, CNC machines and instruments are answerable for a large number of the components in most trendy cars.

Because of this machinists make the very best CNC programmers, operators, and setup personnel. Alongside our quarry and mining industry actions we regularly perform general machining work to free difficulty gadgets for a lot of large and native companies in the oil & fuel industries, metal production industries and general engineering sector. There are still some issues in China Ecommerce business which might hinder their prosperity.

With some CNC milling machines, for example, about the only programmable function is axis movement. Searching for companies which offer prime quality and reasonably priced CNC milling service can be indeed a time-consuming process. Precision CNC machining providers together with milling, turning, drilling, CNC lathe work, device presetting, floor grinding, honing and turning. DMG/Mori Seiki's Greg Hyatt, who heads the company's Machining Expertise Laboratory, provides a booth tour for editors during JIMTOF 2010. FSWizard will robotically use recommended reducing velocity and chipload for machining with quite a lot of indexed and solid endmills, drills, faucets and so on.

As a generalization this e-book was written for the Beginner to Intermediate CNC students. I lately talked to AC Manufacturing, cnc machine store situated in Bay Space and so they advised me to look into many alternative apps for android smartfon. On the heart of all CNC machining is the central computer, which is fed data from a CAD program, or laptop aided design software. This kind of function could assist operator course of a wide range of complicated contour components such as CNC Lathe Steel Products. The primary goal of CNC Routing Machines is to repeatedly manufacture advanced components in steel in addition to other supplies, utilizing a specially coded program. Nonetheless, it's quite an costly machine and most business house owners don't begin with a capital sufficiently big to invest in CNC machines.

AKS Slicing Techniques manufactures heavy-responsibility, high-precision CNC Plasma Cutters that deliver the Repeatable Accuracy, High Velocity and Rugged Sturdiness required by essentially the most demanding fabricators and producers. Therefore, the machining process automation, machine tools and to adapt the extent of the composite quantity and small quantity capability have turn into the direction of machine tool technology. See his latest work at Precision CNC Machining Companies and Precision Steel Machining which focuses on the custom manufacturing industry with emphasis on serving to American Machine Retailers entice more prospects. Intense Analysis is the comprehensive collection of market intelligence services out there on air. When positioned collectively in a logical method, a gaggle of CNC phrases make up a command that resemble a sentence. One other option to reduce foam is with a CNC machining services router - this is mainly for machining the froth and not for chopping.

Comments

Post a Comment